PLC and LED Strip Controller Connection: A Step-by-Step Guide

This is a step-by-step guide to connecting a PLC (Programmable Logic Controller) to an LED Strip Controller.1. Understanding the Basics:, - PLC: A PLC is a digital computer used for automation. It receives input signals, processes them according to a set of instructions, and then sends output signals to control machinery or devices., - LED Strip Controller: This is a device that controls the brightness, color, and other attributes of LED strips. It receives input signals from a source, such as a PLC, and then adjusts the LED strips accordingly.2. Hardware Connection:, - Step 1: Connect the PLC to the LED Strip Controller using an appropriate cable or wire. Ensure that the connection is stable and reliable., - Step 2: Power up the PLC and LED Strip Controller. Verify that they are both functioning properly.3. Software Configuration:, - Step 1: Configure the PLC software to send appropriate input signals to the LED Strip Controller. This may involve setting up communication protocols, such as RS-232 or RS-485, and configuring the PLC to recognize specific inputs from sensors or other devices., - Step 2: Configure the LED Strip Controller software to receive input signals from the PLC and adjust the LED strips accordingly. This may involve selecting the communication protocol, setting up input channels, and defining how the LED strips should respond to different input signals.4. Testing and Verification:, - Step 1: Test the connection by sending input signals from the PLC to the LED Strip Controller and verifying that the LED strips respond as expected. Adjust any necessary settings if needed., - Step 2: Once testing is complete, monitor the system to ensure that it is functioning stably and reliably.This guide provides a basic understanding of how to connect a PLC to an LED Strip Controller and how to configure both hardware and software for optimal performance.

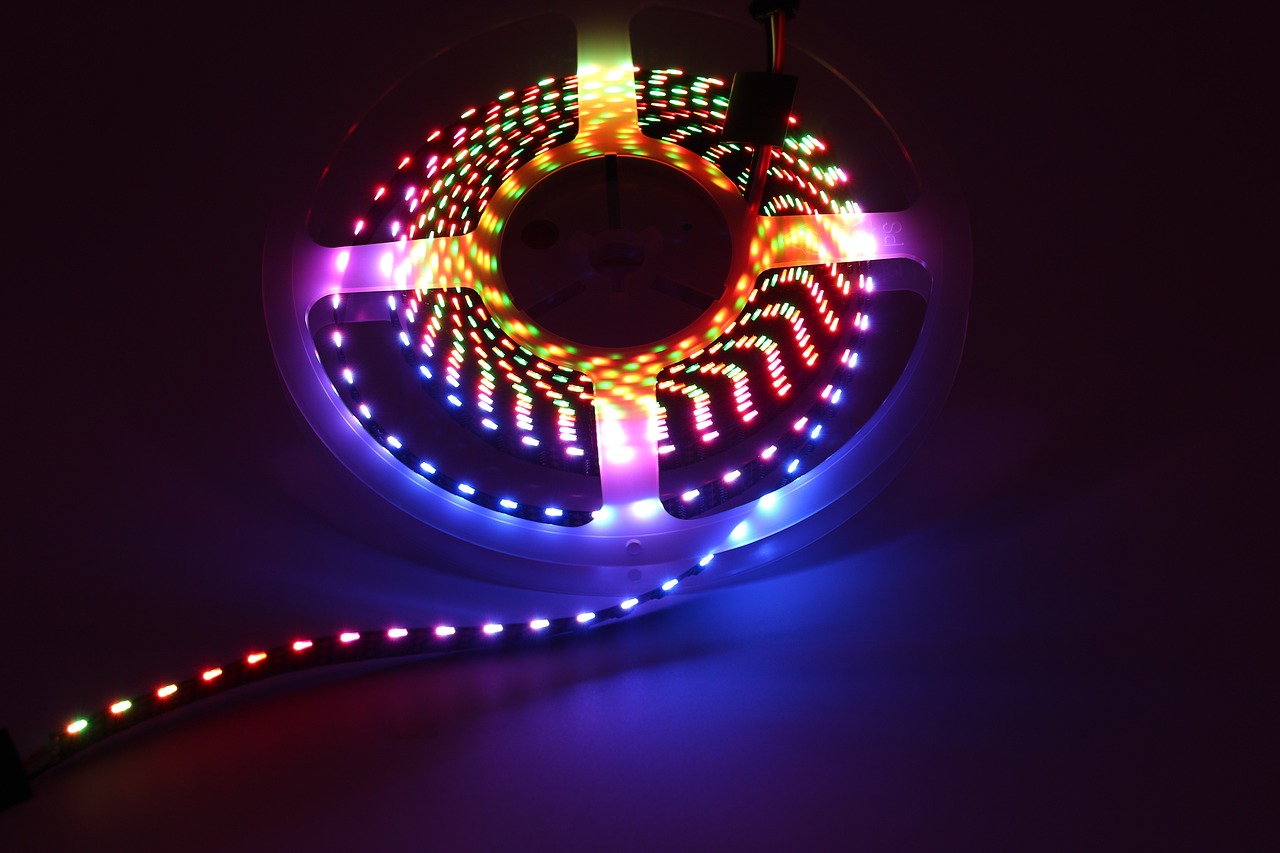

In this article, we will provide a detailed guide on how to connect a PLC (Programmable Logic Controller) to an LED strip controller. This process is essential for automating and managing LED lights in various applications such as smart homes, public displays, and industrial lighting systems. By following the steps outlined below, you will be able to establish a reliable and efficient connection between the PLC and LED strip controller.

1、Hardware Preparation:

- Gather the necessary equipment, including the PLC, LED strip controller, wires, and any other necessary components.

- Ensure that the PLC and LED strip controller are turned off and disconnected from any other devices.

2、Physically Connect the Devices:

- Use the appropriate wires to connect the PLC and LED strip controller. The exact wiring configuration may vary depending on the specific devices you are using, so please refer to the documentation provided by the manufacturer for accurate wiring instructions.

- Ensure that all connections are secure and free from any potential interference or damage.

3、Configure the PLC:

- Open the programming software for the PLC and create a new program or modify an existing one to include the necessary commands for controlling the LED strip.

- Configure the PLC to recognize the LED strip controller as a connected device and set up any necessary input/output mappings.

- Test the PLC configuration by sending test commands to the LED strip controller to ensure everything is working as expected.

4、Configure the LED Strip Controller:

- Turn on the LED strip controller and navigate to its configuration menu.

- Set up the controller to accept commands from the PLC, specifying the communication protocol (e.g., Modbus, BACnet) and any necessary parameters (e.g., baud rate, data bits).

- Configure the LED strip controller to control the actual LED lights based on commands received from the PLC. This may involve setting up specific lighting effects, color sequences, or brightness levels.

- Test the LED strip controller configuration by sending test commands from the PLC to ensure everything is working as expected.

5、Test and Debug:

- Once both the PLC and LED strip controller have been configured, perform a series of tests to ensure that everything is working together properly. This may involve sending different commands from the PLC to control various lighting effects on the LED strip.

- If there are any issues or errors during testing, go back and review the configuration settings for both devices to identify and correct any problems.

- Once testing is complete and everything is working as expected, you can proceed to implement your final application using the PLC and LED strip controller connection setup you have created.

By following these steps carefully, you should be able to establish a reliable and efficient connection between a PLC and an LED strip controller, allowing you to fully automate and manage your LED lighting system with precision and ease of use.

Articles related to the knowledge points of this article:

PLC Controller: Main Roles and Functions