Title:单片机变PLC控制器,技术创新与未来发展的融合

The integration of single-chip microcontrollers into PLC controllers represents a significant technical innovation in the field of automation. This innovation, which combines the processing capabilities of a single-chip microcontroller with the industrial automation features of a PLC, provides a more efficient and cost-effective solution for industrial control applications.The use of single-chip microcontrollers in PLC systems has numerous advantages. They not only enhance the processing speed and efficiency of PLC controllers but also increase their reliability and stability. Additionally, the integration of these microcontrollers allows PLC systems to handle complex algorithms and perform tasks that were previously not possible, further enhancing the capabilities of industrial automation systems.Looking ahead, the future of PLC controllers seems bright, with a focus on enhancing performance, efficiency, and reliability. By integrating cutting-edge technology such as artificial intelligence and machine learning, PLC systems are expected to become even more intelligent and capable of handling complex tasks. This innovation will not only transform PLC controllers but will also drive industrial automation to new heights, leading to more efficient and productive manufacturing processes.

In the world of industrial automation, PLC (Programmable Logic Controller) technology has long been a mainstay for process control, monitoring, and automation of machines and systems. With the evolution of technology, however, the landscape of PLC controllers is rapidly changing. This article delves into the world of single-board computers transforming into PLC controllers and the resulting impact on industrial automation.

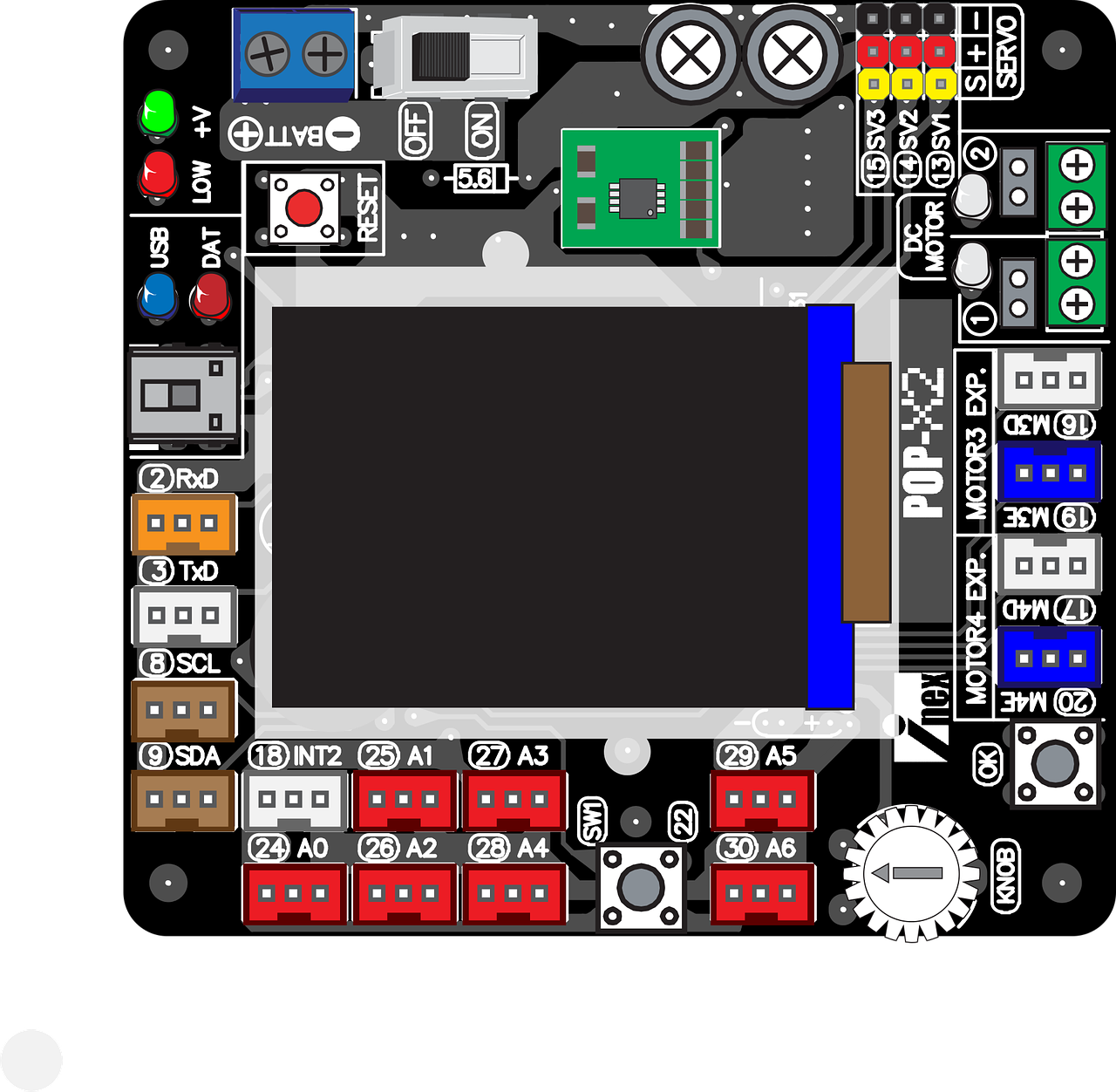

In recent years, single-board computers, commonly known as SBCs, have gained significant attention in the world of robotics and automation. These SBCs, powered by advanced processors and armed with a plethora of communication interfaces, are capable of executing complex tasks with precision. This has led to a paradigm shift in PLC controller design, moving away from traditional hardware-based systems towards software-defined, flexible platforms.

One of the primary advantages of using SBCs as PLC controllers is their adaptability. Traditional PLCs are often limited to specific tasks and have fixed I/O configurations. SBC-based PLC controllers, on the other hand, can be easily reprogrammed to suit different tasks, thanks to their flexible software architecture. This allows for cost-effective solutions that can be adapted to changing industrial requirements.

Moreover, the emergence of new communication protocols and standards such as EtherNet/IP and Profinet has significantly enhanced the connectivity and interoperability of SBC-based PLC controllers. These protocols enable seamless integration with other industrial networks, facilitating data exchange and remote monitoring. As a result, manufacturers can leverage the power of SBCs to build PLC controllers that are not only cost-effective but also highly efficient and easy to integrate.

However, the shift to SBC-based PLC controllers is not without challenges. One major concern is the issue of reliability. SBCs, while offering significant computational power, also introduce complexity and potential for software failures that may not be present in traditional PLCs. This calls for robust software and hardware designs that can withstand the rigors of industrial environments.

To address these challenges, manufacturers and developers are turning to advanced technologies such as artificial intelligence and machine learning. By integrating these technologies into SBC-based PLC controllers, it may be possible to implement self-learning and self-diagnostic capabilities that can help predict and prevent potential failures before they occur. This could significantly enhance the reliability and efficiency of industrial automation systems.

In conclusion, the transformation of single-board computers into PLC controllers is a significant development in the world of industrial automation. By combining the computational power of SBCs with the robustness of PLC technology, we can create highly adaptive and efficient industrial automation solutions that can meet the challenges of a rapidly changing industrial landscape. While there are still challenges to be addressed, innovations in areas such as artificial intelligence and machine learning offer exciting possibilities for the future of industrial automation.

Articles related to the knowledge points of this article:

Beijing PLC Controller: A Comprehensive Guide

Bking and PLC Controllers: Understanding the Basics and Differences

PLC Controller Fault Diagnosis and Troubleshooting