提升效率与质量,智慧线缆生产线的优势与应用

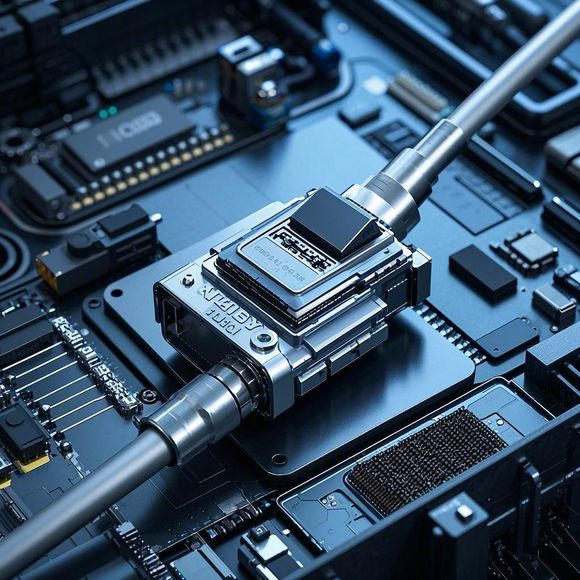

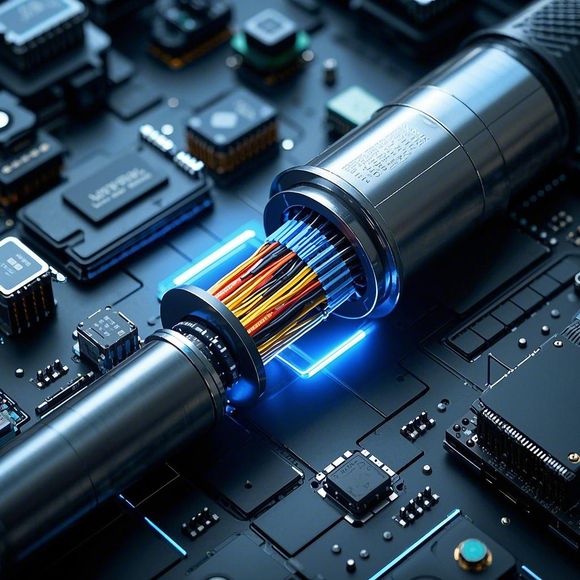

智慧线缆生产线是一种结合了先进技术和自动化系统的创新生产方式,它能够显著提升线缆生产的效率和质量。相比于传统生产线,智慧线缆生产线通过智能化控制和数据实时监测,实现了生产过程的自动化、数字化和智能化。智慧线缆生产线能够自动化完成线缆的制造流程,从原材料处理到成品包装,各个环节都由机器自动完成,减少了人力成本,并提高了生产速度。自动化的导线放卷、绝缘材料包裹、以及在线检测系统,确保了生产过程的高效和稳定。智慧线缆生产线配备了先进的质量控制系统,能够对生产过程中的各项参数进行实时监测和调整。这包括线径控制、绝缘厚度检测、以及耐压测试等,确保每一米线缆都符合严格的质量标准。智慧线缆生产线还具有数据分析和预测能力,通过收集和分析生产数据,可以预测潜在的问题,并及时采取措施,避免质量问题的发生。生产线的数据还可以用于优化生产流程,提高效率,降低成本。智慧线缆生产线的应用不仅限于线缆制造业,它还能够为其他相关行业提供高质量的线缆产品,如电力、通信、汽车等。在电力行业,智慧线缆生产线生产的耐高压、耐高温线缆,能够提高电力传输效率,保障电网安全。智慧线缆生产线的出现,不仅改变了传统线缆生产的模式,还为各个行业提供了更加可靠和高效的线缆解决方案。随着技术的不断进步,智慧线缆生产线将会越来越智能化,为社会的发展和进步做出更大的贡献。

Hey there! If you're in the market for a game-changer in your cable production game, then you've gotta check out the latest in smart cable manufacturing: the intelligent cable production line! It's like the Iron Man suit for your factory, boosting efficiency and quality like never before.

So, what exactly is a smart cable production line? It's a state-of-the-art system that uses cutting-edge technology to automate and optimize every stage of the cable production process. From design to distribution, these lines are packed with features that'll make your competitors green with envy.

First off, let's talk about customization. With the intelligent cable production line, you can say goodbye to one-size-fits-all cables. This system allows for on-the-fly customization, so you can produce cables tailored to your clients' exact specifications. It's like having a personal tailor for your wires!

But customization is just the beginning. These lines are also all about efficiency. They use advanced robotics and AI to streamline the production process, reducing lead times and increasing output. Plus, with real-time monitoring and analytics, you can quickly identify and resolve any issues, ensuring your cables are always rolling off the line at top speed.

Quality control is another area where the smart cable production line shines. With built-in sensors and AI algorithms, these lines can detect even the slightest deviation from your quality standards. This means you can deliver cables that are not just customized but also consistently top-notch.

And let's not forget about sustainability. The intelligent cable production line is designed with the environment in mind. It reduces waste, energy consumption, and even the carbon footprint of your operations. It's a win-win for your business and the planet.

But don't just take my word for it. Imagine being able to produce cables that are not only customized and high-quality but also delivered faster than ever before, all while doing your part for the environment. That's the power of the smart cable production line.

So, if you're ready to revolutionize your cable production, it's time to embrace the future today. Upgrade to the intelligent cable production line and watch your business soar to new heights of efficiency, quality, and customer satisfaction. Your competitors are already jealous, so what are you waiting for? Let's get you plugged into the future!

Content expansion reading:

In today's world, where technology is at the forefront of every industry, smart cables have emerged as a crucial component in the development of smart homes, smart cities, and other smart infrastructure projects. As an exporter of this product, it is vital to understand the intricacies involved in the production process to ensure that we can cater to the diverse needs of our global clients. Let's delve deeper into the various aspects that contribute to the success of smart cable production and how they affect our operations.

Firstly, let's talk about the importance of quality control during the manufacturing process. Quality assurance is not just about meeting the standards set by regulatory bodies but also ensuring that the final product meets the expectations of our customers. This involves rigorous testing procedures that involve inspecting components for defects, measuring the electrical conductivity and resistance levels to ensure optimal performance, and checking the durability of the cable against potential environmental factors. By employing cutting-edge equipment and implementing stringent quality control measures, we can guarantee a product that stands out from the competition.

Next, let's talk about the significance of advanced manufacturing technologies in enhancing our competitive edge. As technology continues to evolve at a rapid pace, adopting new techniques and tools can help us streamline our production processes and reduce costs. For example, using computerized numerical controls (CNC) machines for precise cutting and drilling can significantly improve accuracy and speed. Additionally, incorporating robotic automation into the assembly line can enhance efficiency and reduce human error. Furthermore, adopting digital twin technologies can help us optimize design and production without compromising on quality.

Moving on to the importance of supply chain management, it cannot be understated how critical it is in ensuring that we meet our customers' demands promptly. A well-managed supply chain involves sourcing raw materials from reliable sources, maintaining inventory levels to avoid stockouts, and ensuring timely delivery of goods to our warehouses or directly to end-customers. By collaborating closely with our suppliers and implementing effective tracking systems, we can minimize lead times and minimize risks associated with delayed shipments. Moreover, implementing sustainable practices in sourcing raw materials and reducing our carbon footprint are also essential in demonstrating our commitment to environmental sustainability.

Another key aspect to consider is the importance of collaboration with international partners. As a multinational company, it is essential to maintain strong relationships with our suppliers, distributors, and other stakeholders across borders. Building trust and mutual understanding through regular communication and shared objectives can help us achieve common goals and overcome challenges that arise in the supply chain. Collaboration also allows us to leverage each other's strengths and expertise, resulting in better outcomes for all parties involved.

Furthermore, it's important to recognize the role of customer service in shaping our brand reputation. Providing exceptional customer support can go a long way in building loyalty and fostering long-term relationships. Ensuring prompt response to customer inquiries, addressing concerns and issues efficiently, and providing personalized solutions can make a significant impact in retaining existing customers and attracting new ones. By prioritizing customer satisfaction, we can differentiate ourselves from competitors and build a strong reputation for excellence in the market.

Lastly, let's not forget the importance of staying updated on industry trends and emerging technologies. Keeping up with the latest advancements in smart cable technology, such as the integration of artificial intelligence (AI) or machine learning algorithms, can help us stay ahead of the curve and provide innovative solutions that meet the evolving needs of our customers. Staying informed about industry regulations, certification requirements, and best practices can also enable us to tailor our products and services accordingly, ensuring compliance and gaining a competitive edge.

In conclusion, smart cable production is not just about meeting the demands of our customers but also about delivering exceptional value and ensuring sustainable growth. By focusing on quality control, adopting advanced manufacturing technologies, managing a robust supply chain, collaborating with international partners, providing exceptional customer service, and staying updated on industry trends, we can build a successful business that thrives in an ever-changing marketplace.

Articles related to the knowledge points of this article:

Recycling Communication Cables: A Sustainable Solution for E-waste Management

Title: Communication Cable Channel Atlas

Coaxial Communication Cable: Properties and Applications

Title: Production of Flame-Retardant Communication Cables