Advanced恒温PLC控制器,技术原理与应用探讨

Advanced Temperature-Controlled PLC Controllers: Technical Principles and Application DiscussionThis abstract presents an overview of the advanced temperature-controlled PLC controllers, focusing on their technical principles and applications. It introduces the concept of PLC controllers and how they are used in industrial automation. The article then delves into the specific features of advanced PLC controllers, including their ability to maintain consistent temperature control, improve energy efficiency, and enhance overall system performance. Furthermore, it discusses the various applications of these controllers in different industries such as manufacturing, food processing, and chemical processing. The abstract concludes with a summary of the importance of advanced PLC controllers in improving process efficiency and product quality.

Introduction:

随着工业自动化技术的飞速发展,恒温PLC控制器作为现代工业控制系统中不可或缺的一部分,其在精确控制温度方面发挥着至关重要的作用,本文将深入探讨恒温PLC控制器的基本原理、技术特点、应用领域以及未来发展趋势。

Section 1: Basic Principles of 恒温PLC控制器

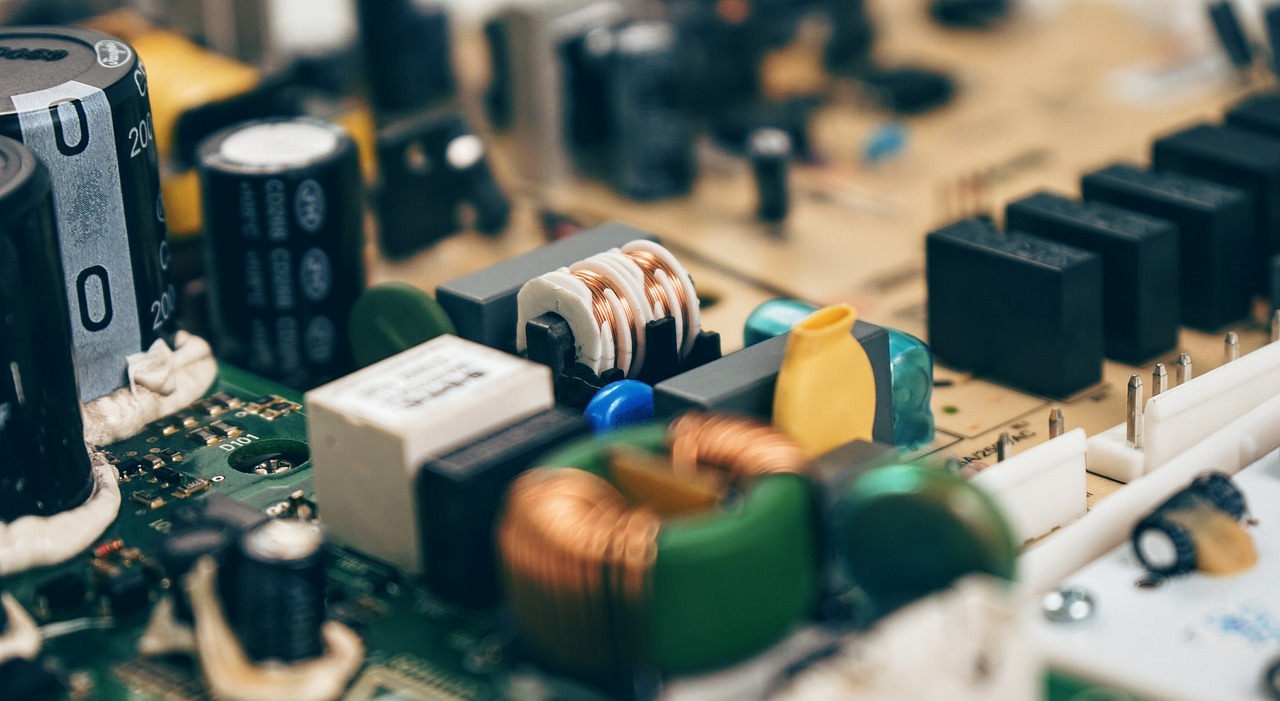

恒温PLC控制器是一种基于可编程逻辑控制器(PLC)技术的温度控制装置,其核心原理是通过数字控制技术实现对温度变量的精确控制,PLC控制器内部集成了微处理器和专用算法,能够接收温度传感器的信号,并根据设定的温度参数进行智能调节,其主要组成部分包括微处理器、传感器接口、模拟数字转换器、控制算法以及输出驱动电路等。

Section 2: 技术特点

恒温PLC控制器具备多种显著的技术特点,使其在现代工业控制中表现出强大的优势:

1、精确性:通过先进的控制算法和微处理器技术,恒温PLC控制器能够实现温度的精确控制,确保工业生产过程中的温度稳定性。

2、灵活性:PLC控制器采用模块化设计,可方便地根据实际需求进行配置和扩展,适应不同工业应用场景的需求。

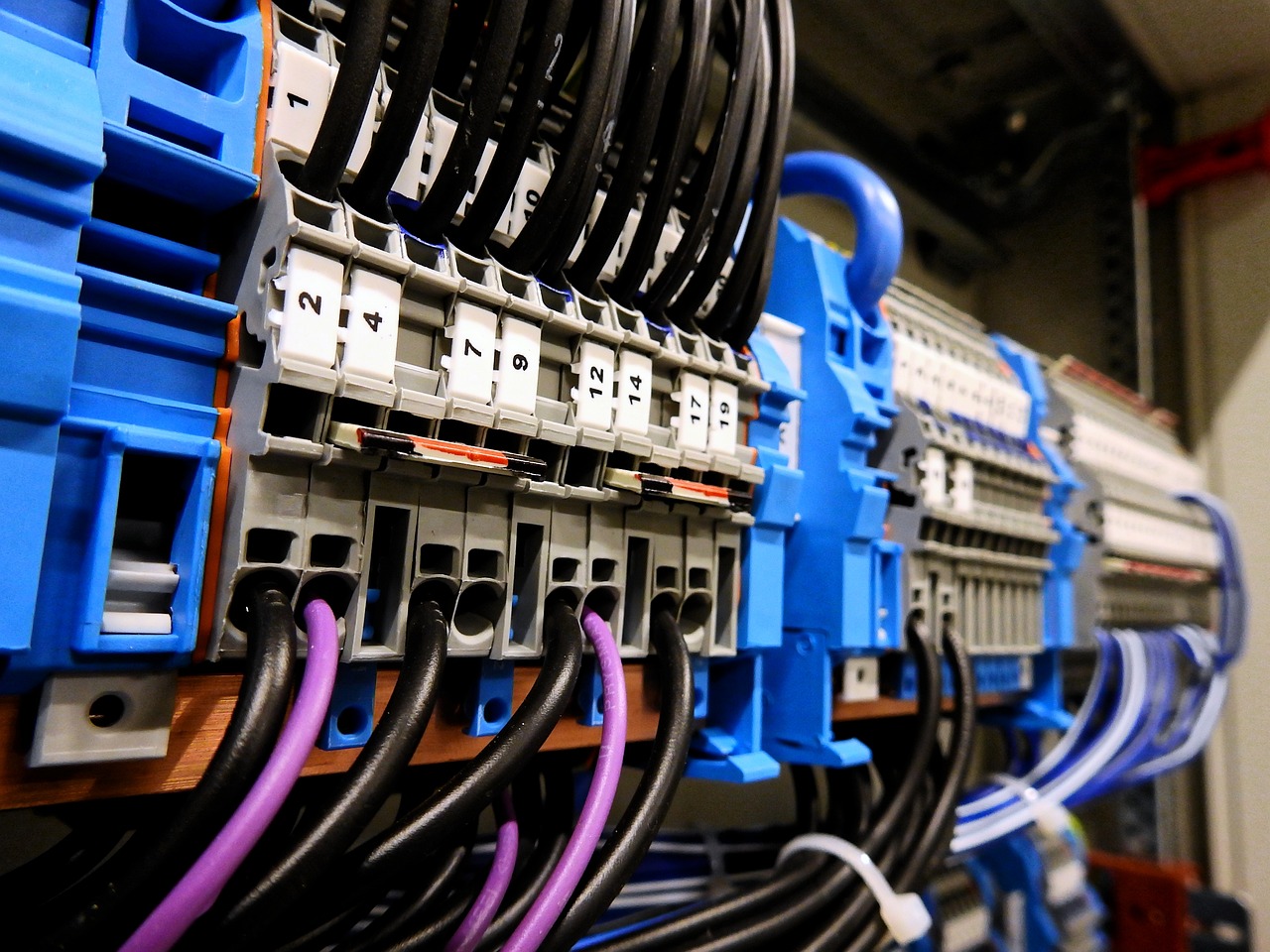

3、可靠性:PLC控制器采用高可靠性元件,具备强大的抗干扰能力和稳定性,确保在恶劣的工业环境中稳定运行。

4、易于编程和维护:PLC控制器采用易于理解和操作的编程语言,使得控制系统的设置、调试和维护更加便捷。

Section 3: 应用领域

恒温PLC控制器广泛应用于各个工业领域,尤其在需要精确控制温度的场合表现出显著的优势:

1、制造业:在塑料、橡胶、冶金、食品加工等制造行业中,恒温PLC控制器用于精确控制生产过程中的温度,提高产品质量和产量。

2、化工工业:在化学反应过程中,温度的控制至关重要,恒温PLC控制器能够确保反应在设定的温度条件下进行,提高反应效率。

3、能源行业:在电力、热能等领域,恒温PLC控制器用于控制发电设备和热交换器的温度,确保设备的稳定运行。

4、医药工业:在药品生产和实验室环境中,温度的精确控制对产品质量和安全至关重要,恒温PLC控制器能够满足医药行业的严格要求。

Section 4: 未来发展趋势

随着科技的进步和工业需求的不断增长,恒温PLC控制器在未来将面临以下几个发展趋势:

1、智能化:随着人工智能和机器学习技术的发展,恒温PLC控制器将实现更高级的智能控制功能,如自适应控制和预测控制。

2、物联网集成:通过与物联网技术的集成,恒温PLC控制器能够实现远程监控和控制,提高生产效率和能源利用率。

3、模块化与个性化:随着模块化设计的进一步发展,恒温PLC控制器将更易于配置和定制,以满足不同工业应用场景的个性化需求。

4、高性能与高可靠性:为提高生产效率和产品质量,恒温PLC控制器将不断提高控制精度和可靠性,以适应更广泛的应用领域。

Conclusion:

恒温PLC控制器作为现代工业控制系统的重要组成部分,其在精确控制温度方面发挥着至关重要的作用,本文深入探讨了恒温PLC控制器的基本原理、技术特点、应用领域以及未来发展趋势,随着科技的不断发展,我们有理由相信,恒温PLC控制器将在未来展现出更广阔的应用前景和更高的性能表现。

Introduction:

In the realm of industrial automation, temperature controllers play a crucial role in maintaining consistent levels of process temperatures. With their ability to sense temperature variations and respond accordingly, they ensure that production processes run smoothly without compromising product quality or safety. Among the myriad types of temperature controllers available, Programmable Logic Controllers (PLCs) have emerged as one of the most reliable and versatile options. In this guide, we will delve into the world of PLC-based temperature control systems and explore their features, benefits, and implementation strategies.

Features of PLCs for Temperature Control:

1、High Precision and Accuracy:

PLCs are designed to operate with high precision and accuracy, ensuring that temperature fluctuations within a specific range can be accurately monitored and controlled. This is achieved through the use of sensors, which are highly sensitive and precise in detecting temperature changes.

2、Robustness and Durability:

PLCs, like other industrial control systems, are built to withstand extreme conditions and operate reliably over long periods. They are designed to withstand harsh environments, such as high humidity, dust, and corrosive chemicals, making them ideal for use in various industrial applications.

3、Easy Programming and Interfacing:

PLCs come with user-friendly programming software that allows for easy integration with other systems. They support multiple programming languages and can be easily customized to meet specific application requirements. Additionally, PLCs can be easily integrated with other hardware components, such as motors, valves, and sensors, to create comprehensive temperature control systems.

4、Scalability and Flexibility:

PLCs offer great scalability and flexibility, allowing for easy expansion and modification as the needs of the system change. This makes them ideal for complex industrial applications that require continuous monitoring and adjustment of temperature levels.

Benefits of PLC-Based Temperature Control:

1、Cost-Effectiveness:

Compared to other temperature control systems, PLC-based systems can provide significant cost savings due to their high level of reliability, efficiency, and ease of integration.

2、Reduced Downtime:

PLC-based temperature control systems are designed to minimize downtime by providing real-time monitoring and adjustment of temperature levels. This helps to maintain production rates and reduce the risk of equipment damage or failure.

3、Enhanced Safety:

By providing accurate and reliable temperature control, PLC-based systems help to enhance safety in various industries. For example, in chemical manufacturing, proper temperature control prevents dangerous reactions from taking place. In food processing, it ensures that food remains fresh and safe to eat.

Implementation Strategies with PLCs:

1、System Design:

Before implementing a temperature control system using PLCs, it's essential to design a system that meets the specific requirements of the application. This includes selecting appropriate sensors, selecting the appropriate PLC model, and determining the required inputs and outputs.

2、Sensor Placement:

Sensor placement is critical in ensuring accurate temperature measurements. It's important to place sensors strategically to capture the temperature variations across the process area. Proper sensor placement also helps to reduce noise interference and improve the accuracy of temperature readings.

3、Programming and Configuration:

PLC programming involves configuring sensor inputs and outputs, setting up alarm limits, and creating logic to control temperature levels based on preset criteria. It's important to test the system thoroughly before finalizing the configuration to ensure that it works as expected.

Conclusion:

Programmable Logic Controllers (PLCs) represent a powerful tool for controlling temperature levels in industrial processes. With their high precision, robustness, ease of programming, and scalability, PLCs offer unparalleled advantages in temperature control applications. By understanding the key features and benefits of PLC-based temperature control, industrial professionals can make informed decisions about integrating this technology into their systems to optimize performance, reduce downtime, and enhance safety.

Articles related to the knowledge points of this article:

PLC Programming Controllers: The Heart of Automation

PLC Main Controller: The Heart of Industrial Automation

The Price of PLC Controllers in Chizhou

PLC and Controller Networking: A Guide to Effective Implementation