Title: Design of a Mitsubishi PLC Programmable Logic Controller in Shanghai

In Shanghai, the design of a Mitsubishi PLC programmable logic controller (PLC) is crucial for automating industrial processes and enhancing overall efficiency. PLCs are integral to modern manufacturing and processing operations, playing a vital role in monitoring, managing, and controlling various processes and systems. The Mitsubishi PLC, in particular, is renowned for its reliability, performance, and versatility, making it an ideal choice for a wide range of industrial applications.In the design of a Mitsubishi PLC, it is essential to consider the specific needs of the industrial process or application. This includes determining the inputs and outputs required, as well as the logic and sequencing needed to control the process effectively. The design process typically involves identifying the desired functionality, drawing up a detailed schematic, and then programming the PLC to implement that functionality. This programming process requires a deep understanding of the Mitsubishi PLC language and its capabilities.Once the Mitsubishi PLC has been designed and programmed, it can be installed into the industrial process or application. From there, it can monitor and control the process, ensuring that it runs smoothly and efficiently. The Mitsubishi PLC can also provide data and feedback to help operators understand the performance of the process and identify any areas where improvement is needed.Overall, the design of a Mitsubishi PLC in Shanghai is a crucial step in automating industrial processes and enhancing overall efficiency. With its reliability, performance, and versatility, the Mitsubishi PLC is an ideal choice for a wide range of industrial applications.

Abstract:

The Mitsubishi PLC (Programmable Logic Controller) is a key component in modern industrial automation systems, providing a high level of functionality and reliability. In this article, we discuss the design of a Mitsubishi PLC programmable controller in Shanghai, emphasizing the system architecture, hardware components, software programming, and the role of this controller in an industrial automation environment.

I. Introduction

The Mitsubishi PLC programmable controller is an essential device for automating industrial processes. It is designed to monitor and control complex machinery and equipment, ensuring that operations are performed safely, efficiently, and reliably. The controller's design includes a combination of hardware and software components that work together to achieve the desired automation tasks.

II. System Architecture

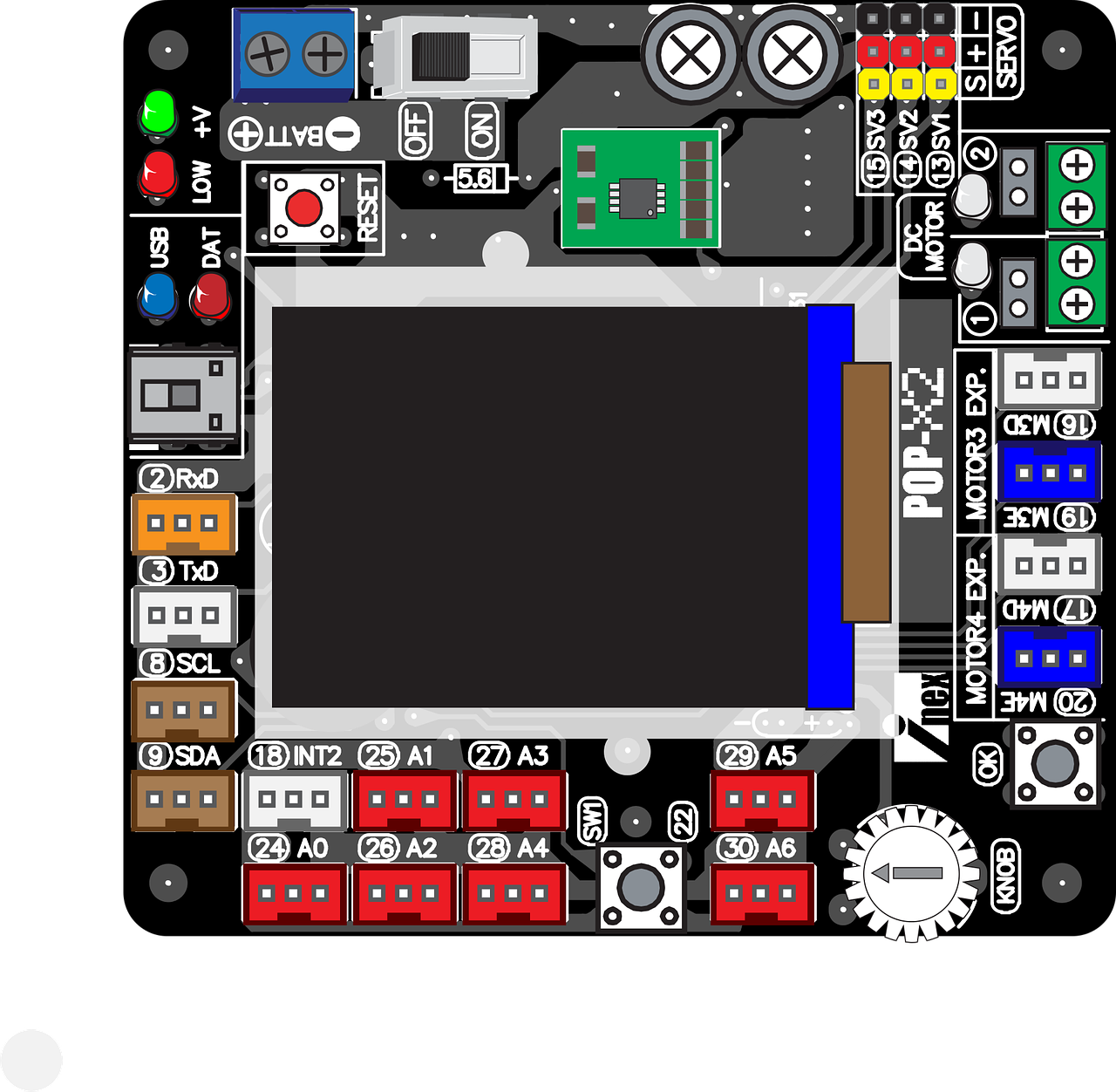

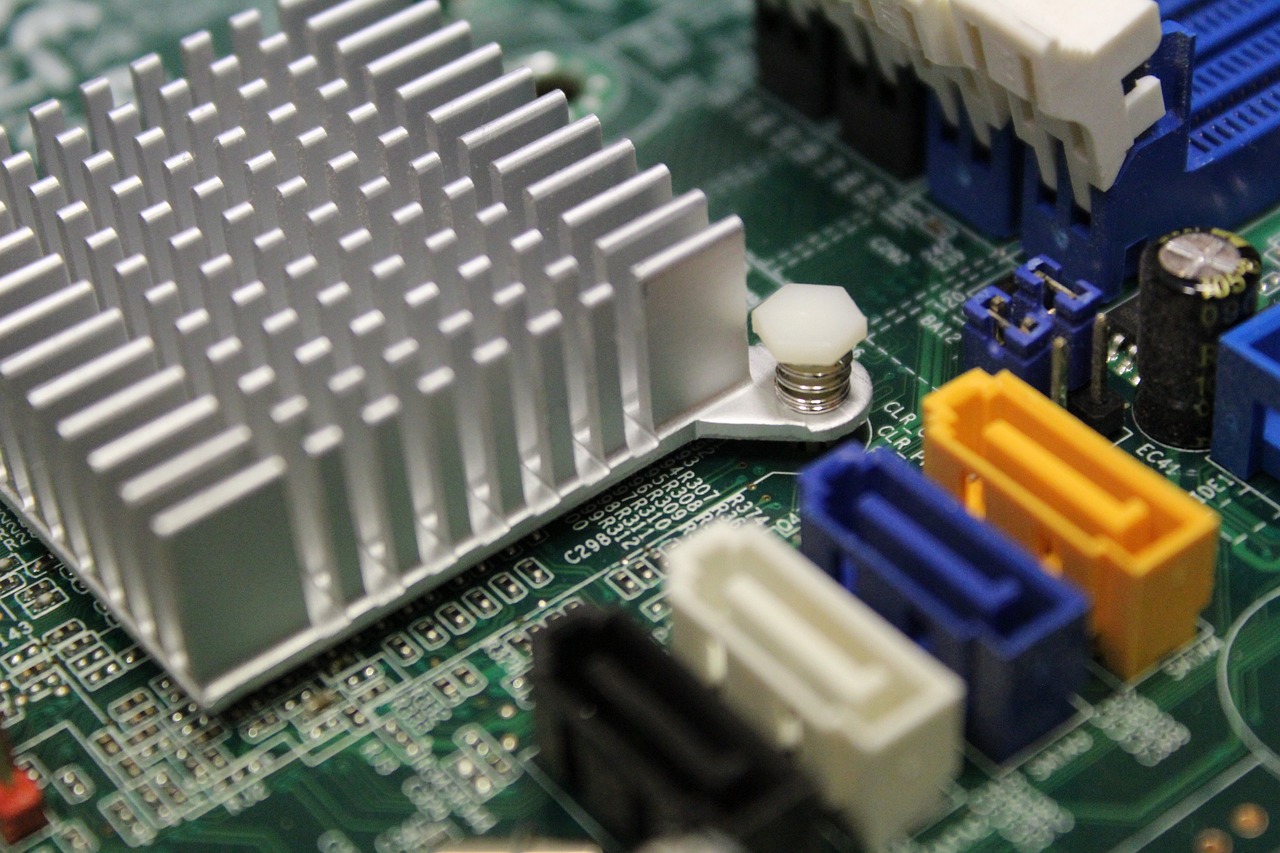

The Mitsubishi PLC programmable controller is built upon a modular design, consisting of a base unit and various expansion modules. The base unit houses the main processing unit, memory, and communication interfaces, while the expansion modules provide additional functionality, such as analog input/output, digital input/output, and special purpose modules. This modular design allows for easy expansion and modification of the controller's capabilities as needed.

III. Hardware Components

The Mitsubishi PLC programmable controller incorporates several key hardware components. The main processing unit, or CPU, is responsible for executing the program instructions and managing data. Memory is used to store the program code, data, and intermediate results. Communication interfaces, such as Ethernet or RS-232, are employed to enable the controller to communicate with other devices or systems. Input/output modules are connected to the base unit via cables or connectors and provide the interface between the controller and the industrial process equipment.

IV. Software Programming

The Mitsubishi PLC programmable controller is programmed using a combination of ladder logic, function blocks, and structured text programming languages. Ladder logic is a graphical programming environment that allows users to create simple or complex logic circuits using a drag-and-drop interface. Function blocks provide pre-defined functions that can be called from within a program to perform specific tasks, such as mathematical calculations or data conversion. Structured text is a text-based programming language that allows for more complex program structures and algorithms to be implemented. The software programming environment also includes a debugger and simulator tool that allows users to test and debug their programs before implementing them on the actual controller hardware.

V. Role in Industrial Automation Environment

The Mitsubishi PLC programmable controller plays a crucial role in an industrial automation environment. It acts as the "brain" of the system, monitoring and controlling various aspects of the industrial process. By integrating with sensors, actuators, and other industrial equipment, the controller can ensure that processes are running optimally, safely, and reliably. The ability to program and customize the controller allows for flexible automation solutions to be implemented, tailored to meet the specific needs of each industrial application.

VI. Conclusion

The Mitsubishi PLC programmable controller is a powerful and versatile device for industrial automation applications. Its modular design allows for easy expansion and modification, while its software programming environment provides a high level of flexibility and functionality. By combining hardware and software components effectively, the Mitsubishi PLC programmable controller can play a significant role in improving industrial process efficiency, safety, and reliability.

Articles related to the knowledge points of this article:

Siemens PLC Controller: A Comprehensive Guide

Title: The rise of Taiwans PLC programmable controllers

PLC Controller Online Configuration and Operation

PLC Controller Manufacturers: Key Players in the Global PLC Market