PLC可编程控制器第四个阶段

PLC可编程控制器第四个阶段PLC可编程控制器是一种广泛应用于各种工业控制场景的设备,其第四个阶段主要包括硬件设计、软件设计、测试与优化等方面。在硬件设计方面,需要整合各种传感器、执行器以及通信模块等,以确保控制器能够获取准确的输入信号并输出精确的控制指令。软件设计方面,则需要根据实际需求编写相应的控制算法和程序,以实现特定的控制功能。还需要设计友好的人机交互界面,以方便用户进行操作和监控。在测试与优化方面,需要对PLC控制器进行严格的测试,包括功能测试、性能测试、安全测试等,以确保其稳定性和可靠性。还需要对控制算法和程序进行不断优化,以提高控制效果和效率。针对实际应用场景的需求,可能还需要对PLC控制器进行定制化的开发,以满足特定的控制需求。PLC可编程控制器第四个阶段是一个涉及硬件、软件、测试与优化等多个方面的工作。只有在这些方面都能够得到充分的考虑和实施,才能确保PLC控制器在实际应用中能够发挥其应有的作用。

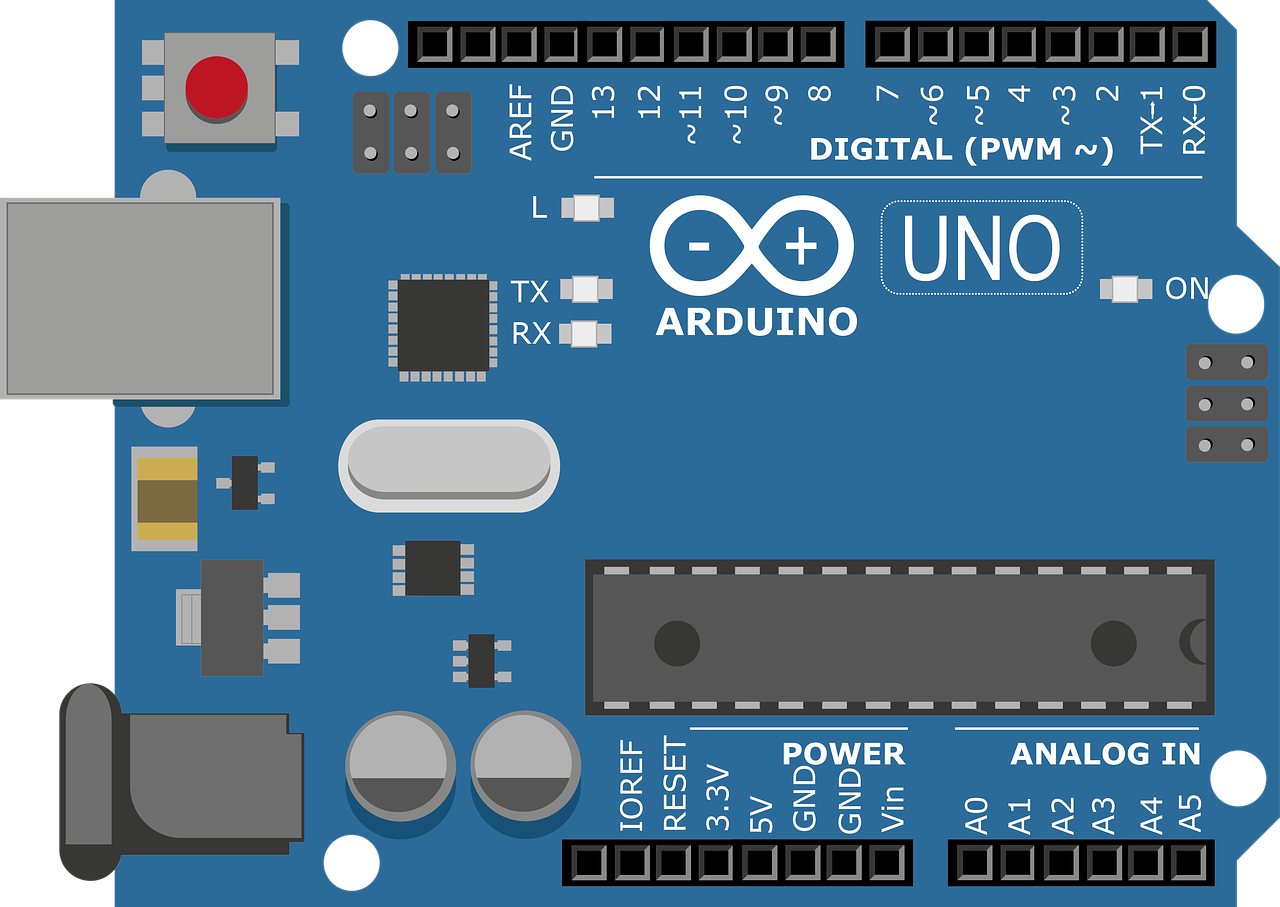

In the fourth stage of PLC programmable controller development, the focus shifts from basic functionality to advanced applications and integration with other systems. PLCs, or Programmable Logic Controllers, are widely used in industrial automation to monitor and control complex processes. As the technology has matured, PLCs have evolved to meet the changing needs of the industry, and the fourth stage is characterized by a shift towards more sophisticated programming techniques and increased system integration.

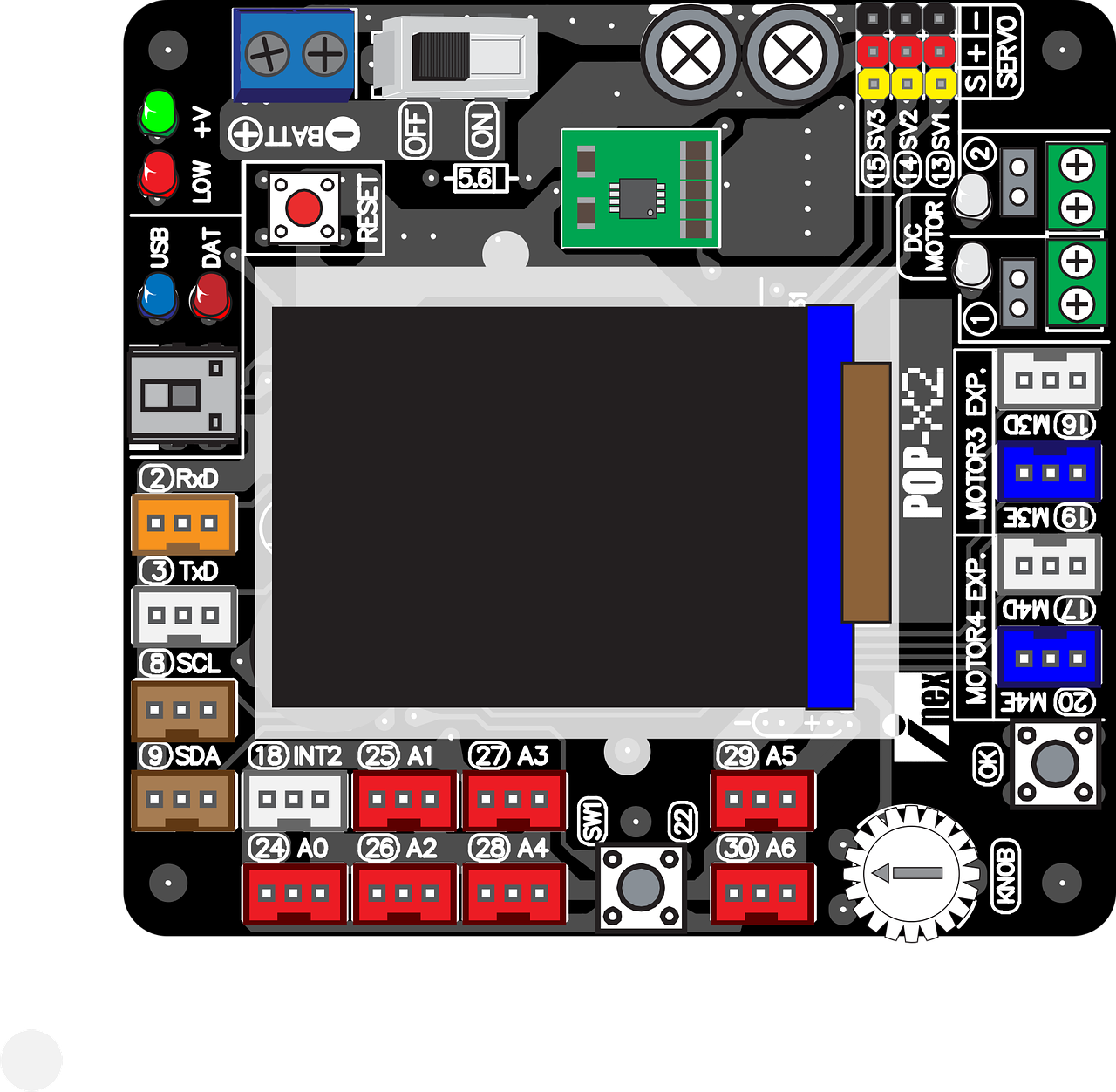

During the fourth stage, PLC programmable controllers begin to handle more complex tasks and provide more advanced features. This includes the ability to handle multiple inputs and outputs simultaneously, as well as more sophisticated logic functions and data processing capabilities. PLCs at this stage are also able to support more user-friendly interfaces, allowing operators to monitor and control the system with greater ease and efficiency.

Another key aspect of the fourth stage is the integration of PLCs with other systems. This integration allows for a more comprehensive solution for industrial automation needs, providing a seamless flow of data and control signals between different systems. This integration also allows for a more efficient use of resources, as data and control signals can be shared between systems, reducing the need for duplicate processing or storage of information.

During the fourth stage, PLC programmable controllers also begin to take advantage of new programming techniques and tools that have become available. These new techniques and tools provide for a more flexible and efficient programming environment, allowing users to create more complex and robust control algorithms. This shift towards more sophisticated programming techniques also allows for a better management of system resources, ensuring that the PLC system is running at its optimal performance level.

In conclusion, the fourth stage of PLC programmable controller development is characterized by a shift towards more complex applications and integration with other systems. At this stage, PLCs are able to handle multiple inputs and outputs simultaneously, provide sophisticated logic functions and data processing capabilities, support user-friendly interfaces, integrate with other systems, and take advantage of new programming techniques and tools. These advancements in PLC technology continue to push the boundaries of industrial automation, providing more efficient and reliable solutions for a wide range of applications.

Articles related to the knowledge points of this article:

PLC Controllers: A Comprehensive Guide

PLC Stepper Controller Nameplate

Pool State PLC Controller Quotes