LED Digital Tube Display PLC Simulator Controller

This LED Digital Tube Display PLC Simulator Controller is a unique and advanced device that combines the functionalities of a PLC simulator with a display controller. It is designed to provide an intuitive and efficient interface for controlling and monitoring LED digital tube displays. The controller features a user-friendly interface that allows operators to easily navigate and manage the display functions. It also includes a built-in PLC simulator that enables users to simulate PLC programming and troubleshoot display issues without requiring a separate PLC simulator device. This innovative controller offers a cost-effective and efficient solution for LED digital tube display applications, making it an ideal choice for both experienced and novice operators.

In today's industrial and technological world, PLC (Programmable Logic Controller) systems play a crucial role in the automation and control of various processes and machines. One of the most important components of a PLC system is the display unit, which provides visual feedback to operators and allows them to monitor and adjust the system's performance.

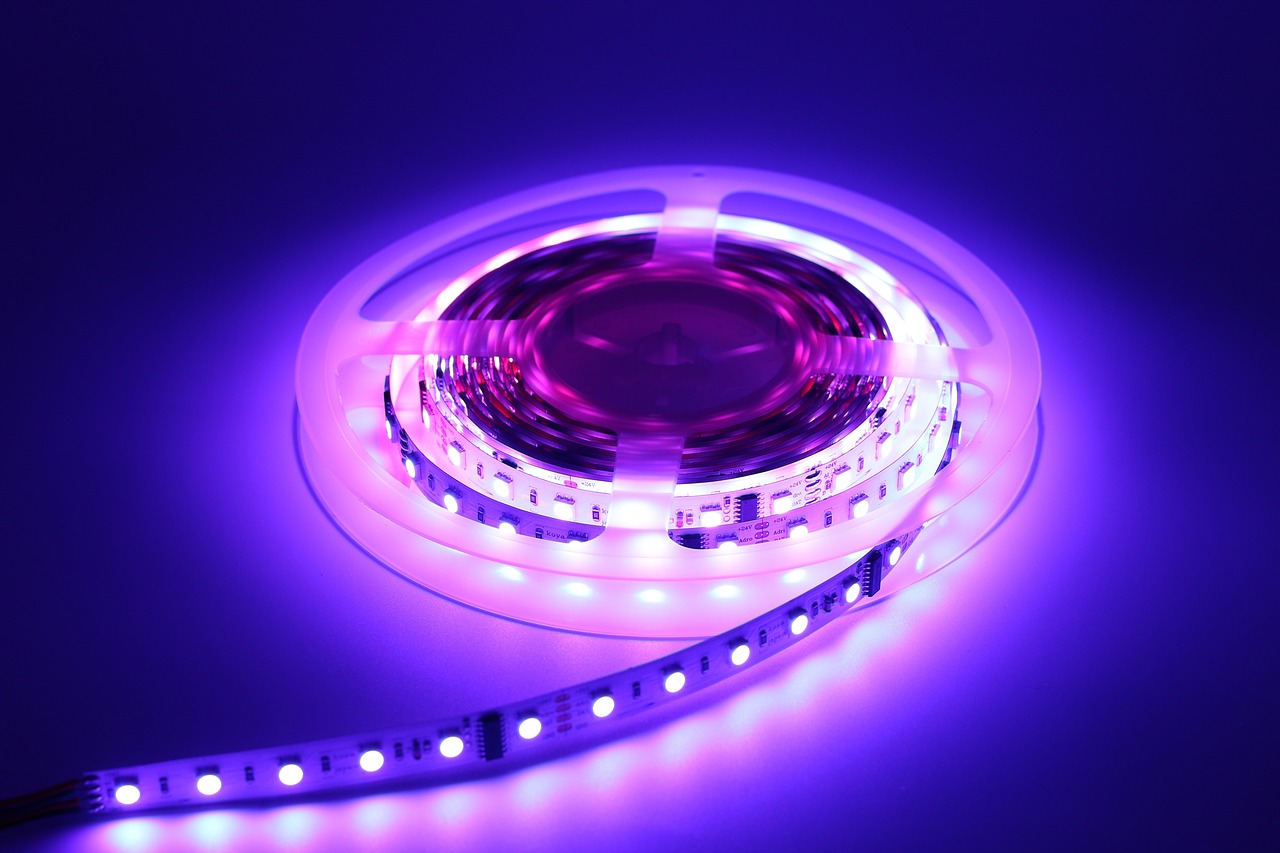

LED digital tube display is a commonly used display technology in PLC systems. It offers a number of advantages over other display technologies, including longer lifespan, lower power consumption, and superior reliability. Moreover, LED displays are also easier to read and provide a clearer visual interface for operators.

In this paper, we will explore the design and implementation of an LED digital tube display PLC simulator controller. This controller will enable us to simulate the behavior of a real PLC system and provide a platform for testing and debugging purposes.

System Design

The LED digital tube display PLC simulator controller consists of two main components: the microcontroller and the LED display module. The microcontroller is responsible for processing the input signals from sensors and actuators, executing the control algorithms, and generating the output signals to control the machines or processes. The LED display module, on the other hand, receives the data from the microcontroller and displays it on the LED digital tubes.

The microcontroller used in this design is a low-cost, high-performance microchip that can be programmed to perform various tasks. It features a built-in timer/counter, interrupt system, and UART (Universal Asynchronous Receiver/Transmitter) interface, which are all essential for implementing the control algorithms and communication with the LED display module.

The LED display module consists of a number of LED digital tubes arranged in a specific pattern or configuration. Each LED tube can display a single hexadecimal digit (0-9 or A-F) and is driven by a dedicated driver circuit. The driver circuit receives the data from the microcontroller via a data line and controls the LED tube to display the corresponding digit.

Implementation

In order to implement the LED digital tube display PLC simulator controller, we need to perform several steps. Firstly, we need to configure the microcontroller to receive input signals from sensors or actuators and generate output signals to control the machines or processes. This can be achieved by programming the microcontroller using a suitable development tool or IDE (Integrated Development Environment).

Secondly, we need to design and implement the LED display module. This involves selecting the appropriate LED digital tubes, driver circuits, and other supporting components. The design should ensure that the LED tubes are properly aligned and spaced so that they can display numbers or letters clearly. Additionally, care should be taken to ensure that the driver circuits are properly powered and can receive data from the microcontroller reliably.

Thirdly, we need to test and debug the entire system. This involves connecting the microcontroller and LED display module together using appropriate cables or connectors and running test programs to verify their functionality. Any issues or bugs found during testing should be identified and resolved promptly to ensure a reliable and accurate simulation environment is created for testing purposes.

Conclusion

In conclusion, an LED digital tube display PLC simulator controller provides an effective platform for testing and debugging PLC systems without requiring actual machines or processes to be present. By simulating real-world inputs and outputs, it allows engineers and technicians to identify and address potential issues early on in the development process thus reducing overall development time and cost. Furthermore, it also provides a valuable tool for training purposes allowing operators to familiarize themselves with PLC systems in a controlled and safe environment prior to working on actual systems in production environment.

Articles related to the knowledge points of this article:

PLC Controller Instruction Numbers

Equipment PLC Controller Alarm

The cost of Huaibei PLC controllers

Zhoushan PLC Controller Manufacturers